Client: Laundry facility, Finland

Outcome: Risk elimination and achievement of environmental compliance

Disruption to facility operations: None

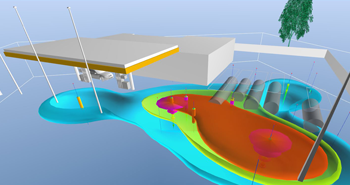

Client: SHELL, Refinery

Disruption to daily operations: None

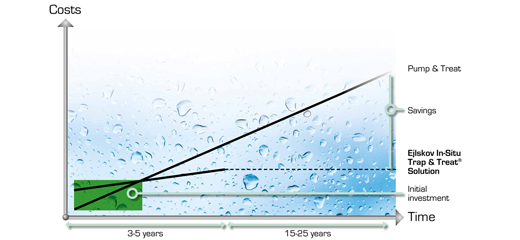

Costings: Client saved approx. 30% compared to excavation

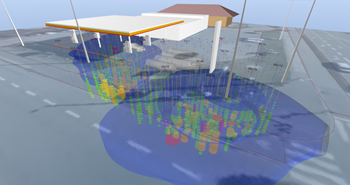

Client: UNO-X, Petrol Station

Petrol Station down time: None

Costings: Client saved 50% compared to the costs of excavation

Client: ST1 OY, Petrol Station

Disruption to daily operation: None

Costings: client saved 50% on costs compared to excavation

Client: Shell, Petrol Station

Petrol station down time: 10 - 12 weeks

Cost comparison: approx. 70% less than excavation with close down and rebuild of entire station

Client: CIRCLE K, Oil and Gas Terminal

Disruption to daily operation: None

Task: Permeabel reactive barrier setup and full scale in-situ remediation on a fixed price contract

Client: HSB, Construction Site

Disruption of building process: None

Costings: Client saved approx. 50% compared to excavation

Shells petrol station in Brøndby, which has been contaminated by a gasoline spill in 2003 and by contaminant residues dating back from the 1980-90s, is now declared officially cleaned up. Ejlskovs patented in-situ biotechnology Trap & Treat® BOS 200® did the job.

Circle K in Sweden signs contract with Ejlskov for the full-scale remediation of a filling station. The filling services at the station will be kept available throughout the operation.

Ejlskov in-situ remediation eliminates soil and groundwater contaminants five times faster than traditional clean-up methods.

Watch this movie to find out how Ejlskov cleans up oil-contaminated sites using innovative and sustainable in-situ technology..