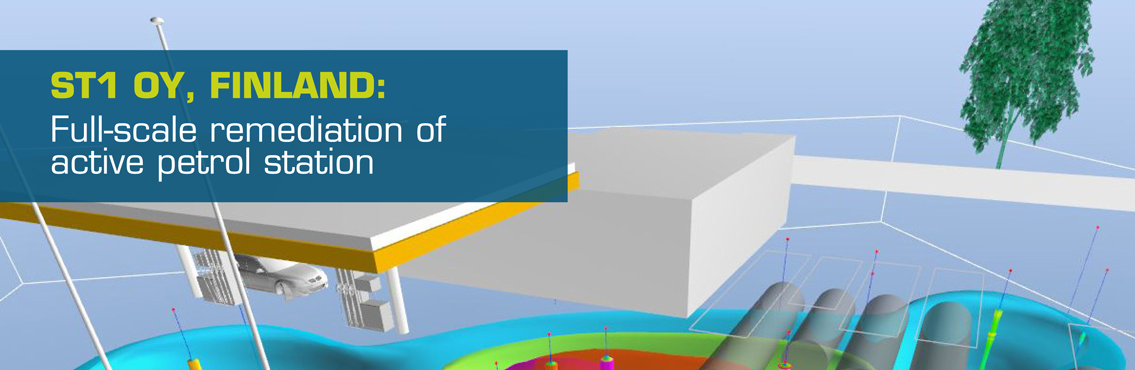

During a previous renovation of underground storage tanks at the Finnish ST1 petrol station, contamination in the upper soil layers had been found and removed. The challenge at this stage for ST1 Oy, was the contamination still present at deeper levels. A solution had to be found for cleaning low permeable soils underneath active tanking facilities without need for expensive and challenging excavation.

The solution

Ejlskov provided a tailor-made plan using our unique Trap & Treat® BOS 200® in-situ technology. A targeted BOS 200® installation was completed from outside the dispenser area using high pressure triangular injection techniques. The result was immediate contaminant plume control and risk removal. Site-specific remediation targets were achieved within a 3-year period in accordance to calculated performance plan and the project was completed without any closedown of tanking services causing no loss of revenue to ST1 Oy. Using Ejlskovs remediation technology, the client saved close to 50 % compared to expenses of a traditional solution as e.g. excavation.

Services provided by Ejlskov

Full-scale application of Trap & Treat® BOS 200® in-situ remediation, including:

• High resolution site investigation and calculation of contaminant mass distribution in soil

• Unique 3D-mapping software for precise and efficient remediation

• Planning of monitoring performance and well installation

Remediation process and results

As a leading European expert in the revolutionary membrane interface probe (MIP) technology, Ejlskov completed a high-resolution site characterization that modelled the geology and the contaminant plume and enabled efficient planning of the injection of Trap & Treat® BOS 200®. A total of 240 injections to a depth of 13 mbgl were made in just over 2 months at the 1200 m2 site.

The overall challenge at this site was to obtain a sufficient Trap & Treat® BOS 200® product distribution in the unsaturated and saturated low permeable soils to create the required immobilization of the BTEX and MTBE compounds and to reach the groundwater aquifer at 11-13 meters inside the treatment area. Ejlskovs flexible drilling equipment and technical expertise enabled a unique approach to remediate this difficult accessible area by using a triangular injection grid pattern with vertical offset injection levels, high pressure top-down injection techniques, and adjustment of the lateral and vertical injection spacing to obtain the best possible product distribution in the subsurface.

All remedial installations were executed without any excavation, and with no disturbance for the ST1-station. The station was kept operational during the entire remediation work. The mechanisms of Trap & Treat® BOS 200® provided immediate contaminant mass-reduction and plum control, and over a 3-year period the biological degradation of BTEX and MTBE brought the underground contamination on the site to safe levels below the criteria agreed with the client.